Imagine this: you’re the CEO of a global manufacturing company, responsible for ensuring that your products reach customers across continents on time and at a competitive price. Your success hinges on a complex network of suppliers, manufacturers, warehouses, and transportation channels. What if you could test your strategies and identify potential bottlenecks before they disrupt your operations? This is where the Harvard Global Supply Chain Management Simulation V2 comes in.

Image: www.albertteboekhorst.com

The Harvard Global Supply Chain Management Simulation V2 is a powerful tool used by businesses and universities worldwide to understand the intricate workings of global supply chains and learn how to optimize their performance. This interactive simulation allows you to experience the challenges and rewards of managing a complex supply chain in a real-world setting, albeit a virtual one. It’s an opportunity to refine your decision-making skills, adapt to unforeseen disruptions, and ultimately become a more effective supply chain leader. But with the pressure of achieving optimal results, many turn to seeking answers. This article delves into the world of the Harvard Global Supply Chain Simulation V2, providing insights and guidance to help you successfully navigate its challenges.

Delving into the Heart of the Simulation

This simulation is more than just a game; it’s a sophisticated learning tool designed to replicate the complexities of global supply chains. The simulation throws you into the role of a company executive, responsible for making strategic decisions across a variety of areas, including:

- Production: Determining optimal production levels, managing inventory, and balancing costs against demand.

- Distribution: Optimizing transportation routes, selecting appropriate transportation modes, and managing warehouse operations.

- Sourcing: Managing supplier relationships, negotiating pricing and lead times, and sourcing raw materials from various locations.

- Finance: Monitoring cash flow, managing working capital, and making strategic investments.

- Marketing: Setting pricing strategies, managing brand perception, and responding to changing market demands.

As you navigate these aspects, you’re faced with real-world challenges such as:

- Fluctuations in demand: Unexpected changes in customer demand can throw off your production plans and lead to stockouts or excess inventory.

- Disruptions to the supply chain: Natural disasters, political instability, and unforeseen events can disrupt transportation routes, impact production, and cause delays.

- Competition: Constant pressure from rivals forces you to optimize your operations and adapt quickly to market changes.

- Financial constraints: Limited resources necessitate careful budgeting and strategic investments to achieve your goals.

The Harvard Global Supply Chain Management Simulation V2 is about balancing these intricate components, making informed decisions, and managing your resources effectively. This is where seeking answers to its challenges becomes valuable, helping you navigate these complexities with clarity and confidently optimize your supply chain.

Unraveling the Key Concepts

While the simulation throws you into the heart of supply chain management, it’s essential to grasp the underlying concepts that drive the simulation and shape effective solutions. Think of these concepts as your compass, guiding you through the complex landscape of the simulation:

1. Supply Chain Planning: This is the foundation of effective supply chain management. It involves forecasting future demand, planning production schedules, and coordinating inventory levels across the entire supply chain.

2. Inventory Management: Finding the delicate balance between holding enough inventory to meet customer demand while minimizing storage costs and the risk of obsolescence is critical. The simulation emphasizes efficient inventory management.

3. Transportation Optimization: Choosing the right transportation modes (air, sea, land) and optimizing routes can significantly impact delivery times, costs, and reliability. The simulation challenges you to make smart transportation decisions.

4. Supplier Management: Building strong relationships with reliable suppliers, negotiating favorable terms, and managing supplier risk are crucial for a successful supply chain. The simulation demonstrates the importance of supplier relationships.

5. Demand Forecasting: Accurately predicting future demand is vital for optimizing production, inventory, and distribution. The simulation highlights the delicate dance of supply and demand forecasting.

6. Risk Management: From natural disasters to economic downturns, unforeseen events can disrupt your supply chain. The simulation emphasizes identifying potential risks and developing contingency plans.

7. Performance Measurement: Tracking key performance indicators (KPIs) such as delivery times, cost per unit, inventory turnover, and customer satisfaction is essential for evaluating your supply chain’s performance and making necessary adjustments. The simulation provides data and tools to assess your performance.

By understanding these key concepts, you’ll not only develop a deeper understanding of the simulation but also lay the groundwork for making informed decisions and achieving optimal outcomes.

Where to Find Answers: Deciphering the Simulation’s Mysteries

Navigating the intricate world of the simulation requires a strategic approach. The good news is that you don’t have to embark on this journey alone. Several resources can provide you with valuable insights and answers:

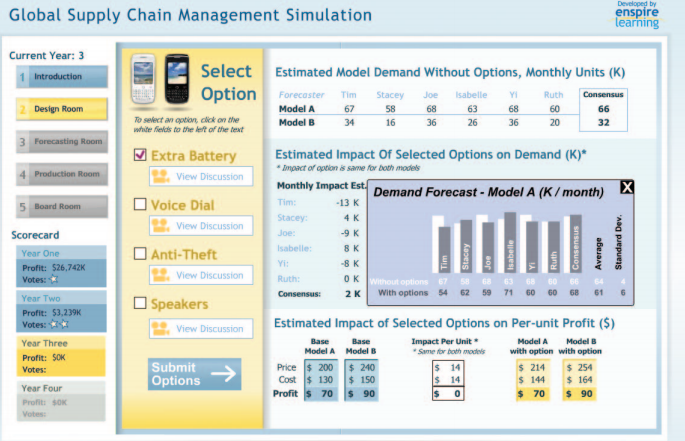

1. The Simulation’s Interface: The simulation itself contains a wealth of information. Pay close attention to the dashboards, reports, and data provided. These tools can offer critical insights into your company’s performance and help you pinpoint areas for improvement.

2. Course Materials and Instructor Guidance: If you’re using the simulation as part of a course, your instructor is a valuable resource. They can provide guidance, clarify concepts, and offer feedback on your decision-making.

3. Online Forums and Communities: Explore online forums dedicated to the Harvard Global Supply Chain Management Simulation V2. Engaging with other users can provide a valuable exchange of ideas, tips, and strategies.

4. Industry Experts and Articles: Research industry experts and articles that focus on supply chain management, logistics, and optimization. Their insights can help you apply best practices to the simulation and enhance your decision-making skills.

5. Online Course Materials: If you are looking for additional support, online courses or videos on the simulation can be a great resource. These resources can offer practical guidance, step-by-step instructions, and insights into different strategies.

Image: www.chegg.com

Leveraging the Answers for Success

The answers you uncover aren’t just about achieving a high score or winning the simulation. They provide you with valuable insights into the intricacies of global supply chain management. Think of these answers as stepping stones to a more strategic and effective approach to managing your own supply chain, whether in a business setting or in your academic pursuits.

1. Prioritize Strategic Thinking: Develop a long-term vision for your supply chain, analyzing trends, predicting demand, and identifying potential risks.

2. Embrace Collaboration: Effective supply chain management requires strong partnerships with suppliers, logistics providers, and other stakeholders.

3. Invest in Technology: Leveraging technology such as supply chain management software, data analytics tools, and simulation platforms can streamline operations and provide valuable insights.

4. Cultivate a Culture of Continuous Improvement: Constantly evaluate and refine your processes, learn from your mistakes, and seize opportunities for optimization.

Remember, the Harvard Global Supply Chain Management Simulation V2 is a powerful tool for shaping your understanding and skills. By effectively utilizing the resources available to you, you can achieve success, gain valuable insights, and embark on a new level of supply chain leadership.

Harvard Global Supply Chain Management Simulation V2 Answers

Conclusion: Embracing the Future of Supply Chain Management

The Harvard Global Supply Chain Management Simulation V2 is more than just a test of knowledge – it’s a window into the future of supply chain management. The simulation challenges you to think strategically, adapt to changing landscapes, and leverage technology to optimize your operations. As you navigate the simulation’s complexities, you’ll emerge with a deeper understanding of global supply chains, a refined set of decision-making skills, and a preparedness to tackle the ever-evolving demands of the modern business world.